|

|

Deck Paint & Stain | Deck Floor Replacement

This picture shows what we call paint and stain. This is where the vertical rails are painted with a solid color stain (usually to match the house) and a transparent coating or semi-transparent stain is applied to the flooring. This will eliminate the chances of the floor peeling. Once the rails however are painted there is no longer the option to go natural in the future. This is a very expensive option for decks because it is very time consuming. We prefer to use PPG Flood on all of our solid color applications. PPG Flood is urethane modified and lasts longer than any competitors solid stain we have used. On existing paint and stains where only the floor needs service, it is very hard to clean the floor without having any of the paint from the rails chip off, there is usually touch ups on the rails that will need to be done. We DO NOT recommend solid color stain to deck floors.

|

| |

|

|

Deck Repair, Building, Construction and Contractors

We offer complete deck services from the repair of one floor board to a complete deck installation. We try to weather our cedar decking prior to installing it, this helps to insure all the wood we install matches up better to the rest of the deck. New cedar lumber has a mill glaze on the wood that acts like a skin and does not allow the stain to penetrate properly causing it to stand out for several years. Most repair companies go to Lowe's or Home Depot and buy new cedar and install it and you have to look at a floor that looks very uneven (old and new boards). We have solved this problem on cedar decks. When we wash and seal a cedar deck all of the boards are very close to matching up when the job is complete. We are unable to do this on Wolmanized or pressue treated decks.

|

| |

|

|

Cedar Lumber & Decking

The cedar that most people are using for decks is not as rot resistant as the cedar that was being used 30 years ago. In the old days, cedar and redwood decks were built from old growth lumber, which was loaded with oils and natural chemicals that made it highly resistant to insect attack and decay. These days, the wood is coming from new growth and managed forests, it contains lots of sapwood. This wood will decay faster. Plus, it cracks and splinters. And if it's not kept treated, it generally looks rough and starts splintering after a few years. Sanding the splinters out of weathered pressure treated 5/4 decking is not possible, it needs to be replaced.

|

| |

|

|

Deck leveling and heaving decks in Michigan

This past spring and fall were one of the worst our state has seen in years, causing many decks in Metro Detroit, Michigan to sink and fall out of level. This deck in Ann Arbor, MI was an example of what we saw on a weekly basis. Our crews replaced 5 posts that were heaving. Michigan code requires you to go at least 42" into the ground. We like to go deeper in areas that are close to wetlands. When deck footings aren't poured deep enough, decks can heave. Sandy, well drained soils aren't particular susceptible to frost heave, while soils with higher clay content are prone to frost heave. This is why itís so important for deck footings to extend down below the frost line. Clay expands causing the ground to push anything out, including concrete and deck poles. Unfortunately, there is no warranty on deck leveling. Unlike handyman, Supreme Deck Restoration, Inc carries full workman's compensation and liability insurance for this type of work.

|

| |

|

|

When to seal a new deck in Michigan?

If you ask 30 people this question, you will most likely get 30 different answers. Different stain companies all have different weathering times as well. For example, Olympic stain can be applied immediately to new pressure treated decks and Twp stain recommends 30 days after the deck is built. Ideally, we recommend that you seal your deck few weeks after it is built. There is no advantage to letting your deck weather. By sealing your new cedar or treated deck you will cut down on the splitting and cupping of the wood. The downside of sealing the deck early is that the product will only last one season because it doesn't penetrate in the wood. Cedar wood has a mill glaze that has to be removed in order for the stain to penetrate. Sanding and pressure washing with mill glaze remover will open up the pores of the cedar wood will help the stain penetrate. If you let the wood weather and dry out for 6 months to a year, the wood will split and warp in the mean time, but the coating will last for two seasons. Depending when the deck is built, we highly recommend to our customers that all new wood get sealed prior to winter even if it means sealing it a few days after it is built.

|

|

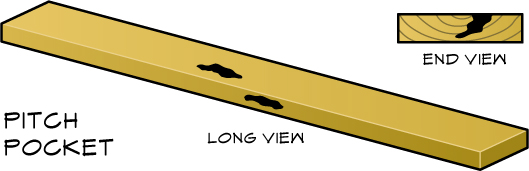

Defects in Pressure Treated or Wolmanized lumber

When sap bleeds from a board it is a "pitch pocket". Pitch pockets can last for years. The "sap" oozing from your deck boards is a natural product of the wood, and it's really pitch, not sap. Running pitch has nothing to do with stains, sealers, or waterproofing the deck. It resides in "pitch pockets" in wood, and when the wood gets hot enough, it melts and runs out. This is most common in yellow pine. Your're most likely to notice pitch problems on the sunny areas of the deck than in shaded sections, as those are the areas on the deck that absorb the most heat. Kiln dried lumber that has been heated to more than 160 degrees usually does not suffer from this problem. The high kiln temperatures solidifies the pitch and prevents it from turning to liquid again. Evidently , the pressure treated lumber used on your deck wasn't dried at a high enough temperature to cause this solidifaction. There is not a lot you can do about the problem except live with it. A bit of turpentine or goo-be-gone on a rag will remove it quickly. Eventually pitch pockets run dry.

|

| |

|

|

We restore, repair, and rebuild King Posts

Most cedar decks start to show rot after 12-17 years starting with the ends of the floor boards. Custom King posts, like this one became popular in the late 1990's. This is custom repair work that is hard to find deck builders or skilled handyman to replace. Many deck builders made kingsposts in their warehouse during winter and were able to assemble them on site. Each kingspost was unique to the builder or contractor. Our carpenters typically take 2-3 hours to repair one kingspost on site or we can replace them all with the ones we stock for less.

Having trouble finding rotted or broken post caps? Mr Spindle can custom make anything you are looking for. This is who we turn to when customers ask us to find them. |

| |

|

JOB 1- Deck Extension

The deck below was extended to add room for a hot tub. We added a header, joists and decking to support the weight of a hot tub. After we pressure washed, cleaned, striped, and the stained the deck in Olympic redwood. |

| Before |

|

|

|

After |

|

|

JOB 2 --Resurface or ReDeck

This is an example of a rotted cedar deck floor that was 12 years old. We replaced the complete decking on the floor. We call this a re-deck or resurface where we used the existing pressure treated framework and laid new cedar decking over top, which saves homeowners a lot of money. In order to use the existing framework the spacing of the joists need to be code and spanned correctly. No permits are needed from your city for a resurface. |

| Before |

|

|

| After |

|

|

| |

| | |